Home » ColdLink

Kaleris ColdLink integrates yard and transportation operations to deliver continuous chain of custody and regulatory compliance.

Kaleris ColdLink™ puts cold chain execution on autopilot by connecting yard, transportation, and warehouse systems in a single, automated feedback loop. Built for grocery, food & beverage, and pharmaceutical supply chains, it turns critical alerts into immediate, coordinated action, exactly where freight is moving. By converging real-time priority, temperature, and fuel data, ColdLink drives faster throughput, reduces loss, and reinforces regulatory readiness, delivering the precision and consistency required to protect inventory and customer trust at scale.

In cold chain operations, there’s no margin for delay, and the quality of your execution is the difference between delivery and loss. Temperature excursions, fuel issues, and missed handoffs don’t just create alerts—they put product quality, compliance, and customer trust at risk. Managing that complexity requires more than visibility. It requires systems that act fast.

Our cold chain solutions are built to give you the momentum to act instantly when conditions change to preserve your perishables.

![]() Pre-Cooling Planning

Pre-Cooling Planning

When you’re responsible for quality-critical products, there’s no margin for “good enough” systems. Your perishable cargo requires a solution that factors in pre-cooling requirements when creating load plans, so your trailers are at the right temperature long before loading begins.

Commodity Separation

You never have to worry about incompatible products sharing space. Built-in commodity rules automatically keep ethylene-producing fruits away from sensitive vegetables—and frozen freight separate from fresh.

![]() Inbound–Outbound Continuity

Inbound–Outbound Continuity

Links outbound store deliveries with inbound supplier pickups to reduce reefer deadhead and maintain temperature continuity.

![]()

ColdLink also supports audit documentation and compliance. It helps to address specific regulatory frameworks for traceability, continuous monitoring, and preventive action for shippers in grocery, food & beverage, and pharmaceuticals.

ColdLink brings transportation, yard operations, and real-time IoT sensing together to maintain an unbroken chain of custody as temperature-sensitive loads move through critical planning and execution handoffs.

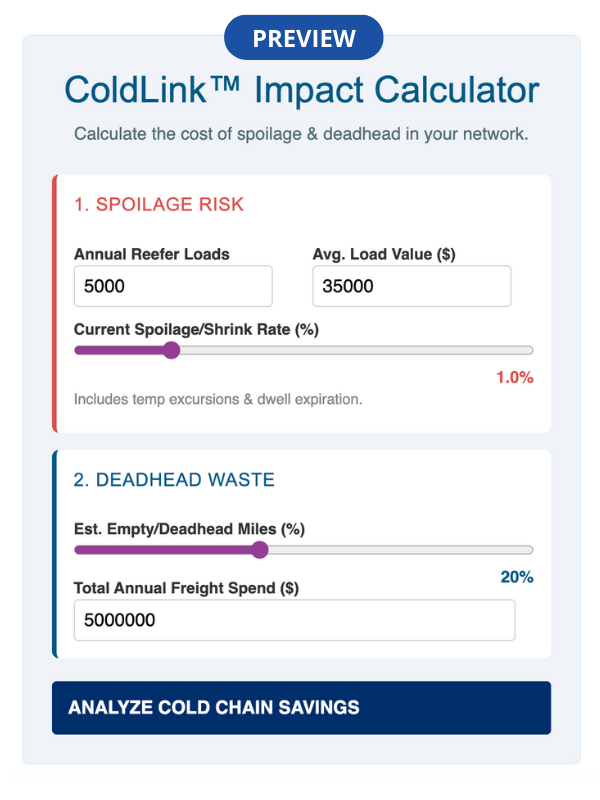

Turn cold chain complexity into measurable impact. See what smarter execution could deliver for your operation.

The moment a truck enters the gate, ColdLink activates a live digital view of the yard. IoT sensors continuously stream reefer temperature, fuel, and operating status, giving teams instant visibility into load health. When a priority shipment shows a temperature deviation or fuel risk, ColdLink dynamically overrides standard FIFO logic and triggers a hot move to the dock. This shift to First-Expiring, First-Out execution reduces dwell time, protects product quality, and minimizes spoilage before it starts.

ColdLink extends execution intelligence for temperature-sensitive operations. Pre-cooling logic ensures trailers reach the correct temperature before loading begins. Commodity separation rules automatically prevent incompatible products from sharing space. Inbound and outbound movements are synchronized to reduce reefer deadhead while maintaining continuous temperature control from supplier to store.

ColdLink embeds audit-ready documentation and compliance directly into cold chain execution. Continuous monitoring, traceability, and preventive controls support regulatory frameworks across grocery, food & beverage, and pharmaceutical supply chains—making compliance a byproduct of how work gets done, not an afterthought.

Ready to drive high performance through optimization at your terminals? Get started with our ebook on the business impact of terminal truck operations.

Most solutions stop at alerts and dashboards. ColdLink goes further by orchestrating action. It connects yard, transportation, and warehouse systems so temperature, fuel, and priority signals automatically trigger the right moves—protecting product quality instead of relying on manual intervention. |

No. ColdLink is designed to integrate with existing TMS, YMS, WMS, and IoT infrastructure. It works within your current operating model, adding an automated feedback loop that improves execution without disrupting daily operations.

ColdLink creates a continuous, documented chain of custody across the yard and in transit. It captures temperature, movement, and decision events automatically, supporting regulatory requirements for traceability, monitoring, and preventive action across grocery, food & beverage, and pharmaceutical supply chains. |

We understand that implementation can seem like an expensive slog, and that incorporating technology to processes that feel intuitive can be a risk. However, manual response can’t match the speed and consistency required for temperature-sensitive freight. Kaleris ColdLink turns real-time conditions into automated action, helping your team prevent spoilage instead of reacting after the fact.

Explore the powerful operational advantages of combining your YMS + TMS

Seamlessly manage your carriers, rates, routes, and loads with a solution designed to evolve with your business needs.

Create and execute the best yard and transportation plan