Improving Process Automation in Terminal Yard Management

What is process automation software?

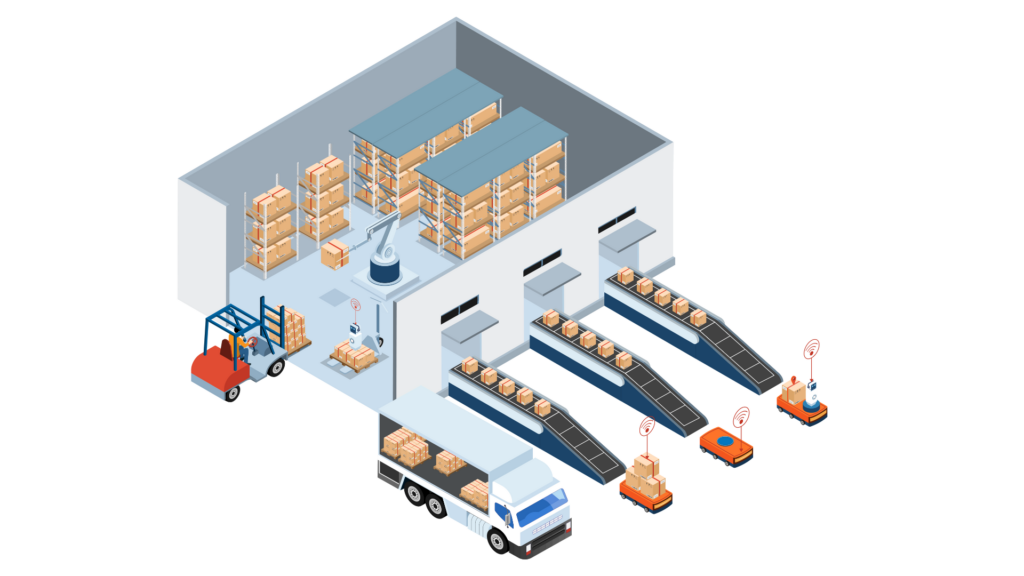

Traditionally, automation is used as equipment automation. So, it’s just the ability to automate the equipment cranes or horizontal transport that we have in our terminals.

And in that space, we want to make sure that we support every type of operation, no matter the vector or type of activity you choose, we can support it. However, we can also support process automation.

We’re trying to make our cost very data driven to augment the capabilities of our users to make better decisions.

Automation Pillars

Equipment Automation

- Faster time to value

- Simpler and faster implementation

- Stepwise approach

User Experience

- Great visibility

- Holistic operational overview

- Data driven recommendations

Decision Making

- Quickly respond to changes

- Intelligent end-to-end decision making

- Continuous value improvements

Digital Models

- A digital real-time version of the terminal

- Continuous value improvements

- Predict your demands

Vision for Equipment Automation Solutions

Stay ahead of the curb by switching from focusing solely deeply technical functions (e.g., scheduling or equipment integration) to putting more emphasis on higher level functions.

Goal: give users a macrovision on operations.

- Provide clear insights what the algorithm is doing and why.

- Alerts to promote proactiveness instead of reactiveness.

- Tool to manage yard performance.

Digital Models to Enable Continuous Optimization

IoT Connectivity

A digital real-time version of the terminal

End to End Optimization

Leverage real-time granular data for terminal-wide integrated and optimized decision making

Predictive & Prescriptive

- Historic data & events

- AI-enabled

- ML-based decisions

- Predict future exceptions

- Recommended prescriptions

Virtual Experiments

Run your terminal offline on different scenarios.

Optimize Operations with “What If” Analysis

An accessible and digitized sandbox version of the terminal.

- Technical simplicity

- Cost adapted to the use and financial capacity of the customer

- Going beyond visibility, to running what-if analysis

Run virtual experiments for any/all of your equipment and operations with Navis – all modeled natively inside N4-NXT.

Ability to adopt new technologies and change

Remove Silos and Increase Process Predictability

- Hybrid Teams

- End-to-end processes

- Change management

Amplify People

- State of mind of the staff

- Knowledge & Training

- Empower staff

Innovation as a Process

- Continues Improvement

- Experience & Expertise

- KPIs & data as a process

Fill out the form below to learn more.