Looking to the Future, Port of Durres Transitions to Modern, Cloud-Based TOS with N4

Hear how Duress chose to be on the cutting edge of technology to provide a competitive advantage over their competitors by selecting Navis TOS

LBCT is the First Fully-Automated Container Terminal in the United States

N4 serves as the brains of the automated operations at LBCT, controlling when the container is supposed to move, which piece of equipment is going to move it and where it’s going

Navis is continuously investing in our technology

As the market leader in Terminal Operating Systems (TOS) for over 30 years, Navis continues to lead and forge innovation with the launch of N4 4.0. Both N4 on-prem customers and new Navis customers are realizing the power of the cloud to lower costs and improve operational efficiencies – all at the same time.

N4 4.0 provides a robust, reliable, consistent terminal user experience that minimizes daily disruptions. N4 allows your terminal real-time access to new features as they are built. Enjoy the benefits of the newest and latest capabilities of N4 4.0 to optimize your terminal’s day-to-day operations, saving your terminal time and money.

Optimization Modules

All terminals, regardless of the operational type, have to maximize the use of their limited resources. N4 optimization solutions help terminal operators automate decision-making and elevate productivity across critical operational and business processes. N4 optimization modules take a holistic approach to streamlining operations to ensure that land, labor, and equipment are used most productively.

Yard Planning

N4 Expert Decking automates yard planning by distributing containers throughout the yard based on pre-defined business rules.

Prime Route

N4 PrimeRoute enables optimal, real-time routing, dispatching and monitoring of straddle carriers, terminal tractors and other internal transportation vehicles within the container terminal

Vessel Autostow

N4 Vessel Autostow automatically generates stowage plans for the entire ship or by specific bay based on rules set by the ship planner in compliance with the vessel planning stowage strategy

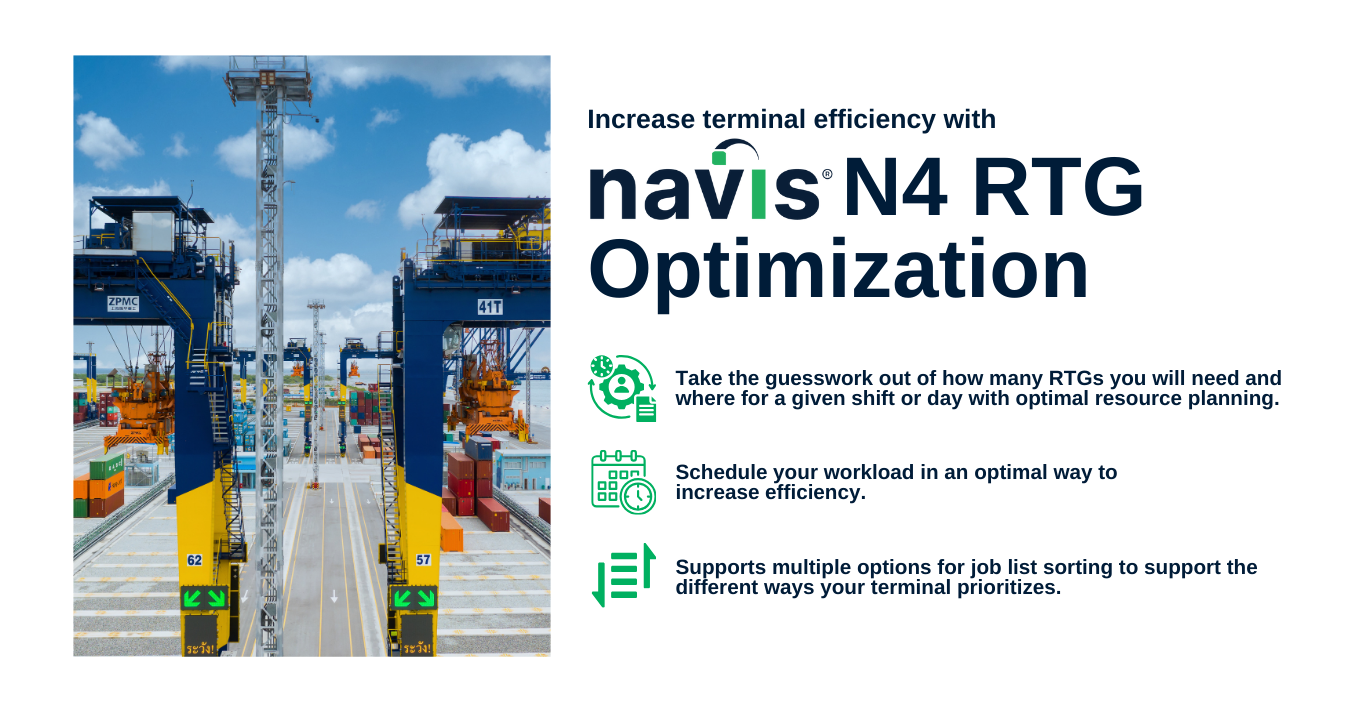

RTG Optimization

With manual RTG operations, valuable time can be lost when RTG drivers need to decide the next optimal job. RTG Optimization is designed to help optimize your side-loading yard cranes decisions

RTG Automation

When terminal conditions are advanced and workers on the ground have limited visibility, automation is a cost-effective solution to ensure optimal terminal productivity

VMT

Vehical Mounted Terminal (VMT) is the next-generation console for RTG and RMG drivers that seamlessly integrates with RTG Optimization, providing an intuitive user interface that enables them to easily complete jobs.

Control Room

Control Room centralizes views and functions critical to monitoring and maintaining operations. It allows operators to visualize where containers, cranes, and trucks are in the yard in a graphical and non-abstracted way.