Home » Terminal Operating System

Optimize mission critical operations with a TOS built to empower performance and profitability

Gain the competitive edge with software that matches the complexities of your operation

Connecting ports, terminals, distribution centers, and partners under one platform.

Measure terminal productivity KPIs with real-time data for container throughput and gate performance

Improve compliance and reporting to improve operational costs.

Improve operational safety whether you’re semi-automated or fully-automated.

Handles all major EDI for container cargo and support integrations with various systems via EVP.

Capture billable events (CBM, FRT/Revenue Tons etc), manage contracts and invoices.

For over 30 years, Kaleris terminal operating technology has been at the forefront of supply chain innovation, continuously evolving to meet the needs of terminal operators worldwide.

The most advanced terminal operating system on the market. It offers various externalization & integration opportunities and advanced optimization modules.

Manage multi-cargo terminal operations including containers, bulk, break bulk, and project cargo, automobiles, trucks, semi-trailer trucks, trailers, and railroad cars.

A simple, cost-efficient TOS for container terminals. It is easier to deploy, flexible and has a quick time to value – replacing legacy TOS systems.

Halting operations for hours or days to perform a technology upgrade is unrealistic.

A flexible terminal operating software solution grows with you and adapts to your needs. That’s why Kaleris TOS offers stepwise implementation, empowering businesses to turn their terminal’s data into powerful performance insights.

With over 560 live sites, terminals of all sizes and types are efficiently and cost-effectively managed.

Pivot quickly to changing market conditions and fluctuating volumes while maintaining customer service levels.

Get in touch with an expert today to get matched with the most effective TOS for your operation.

We proactively develop new capabilities for modern, secure solutions that grow with you.

In today’s fast-paced supply chain industry, Kaleris helps businesses enhance connectivity and productivity.

Marine terminals today face intense pressure from shipping lines, shippers, and evolving global trade demands. The answer isn’t more complexity—it’s smarter, connected infrastructure.

The Kaleris Enterprise and Visibility Platform APIs empowers terminals to deliver faster, collaborate better, and operate more resiliently.

Our solutions are designed with enterprise-grade security to protect your data and ensure compliance with industry standards. Visit our Compliance page to learn more about how we’re ensuring safety protocols for our partners and customers.

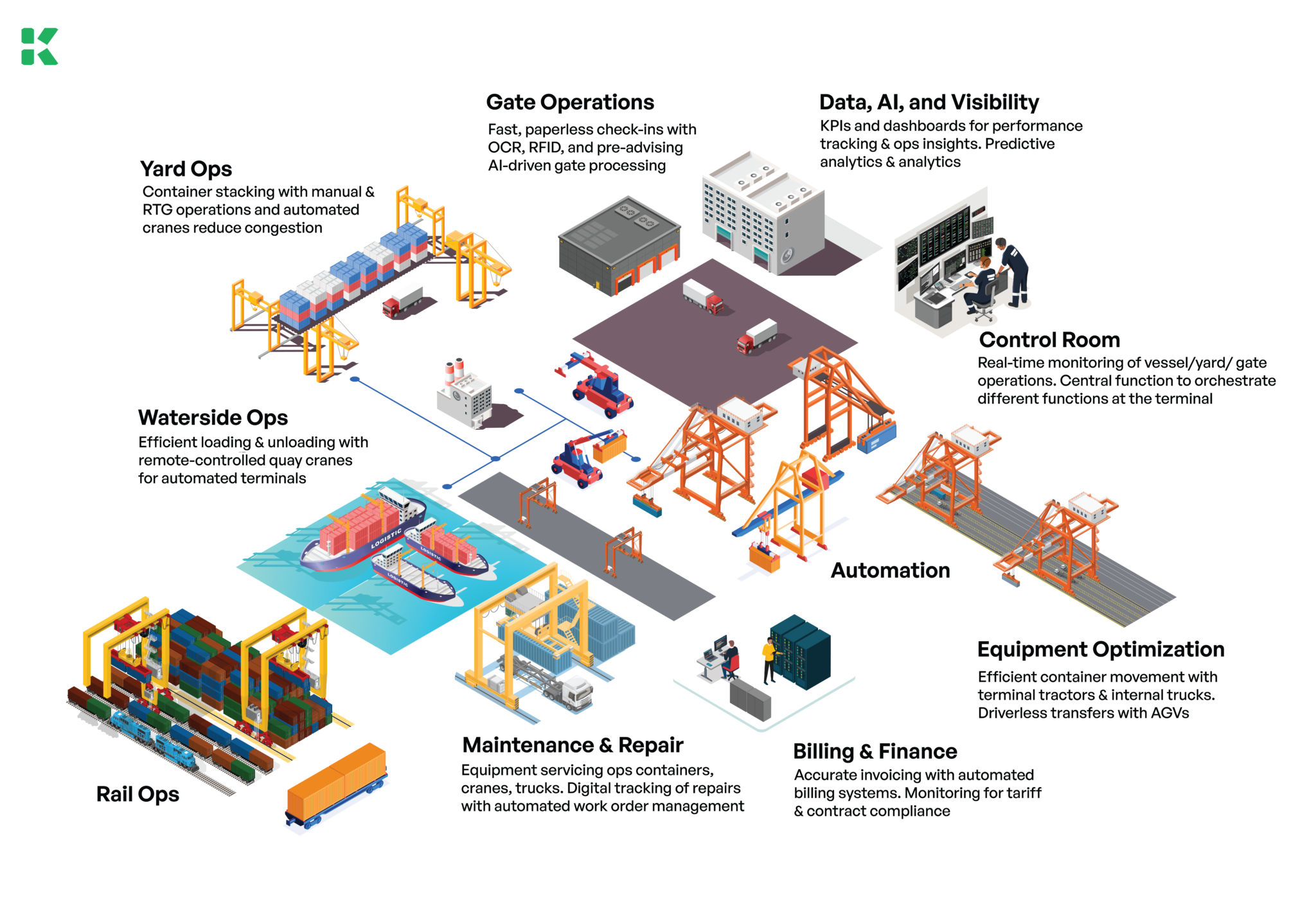

Our digital platform automates the parts of your terminal that you care about most, regardless of the size or scale of your operation – the berth, the yard, and the gate.

Improve planning and decision-making support for vessel visits

Our customers are transforming their supply chains — and talking about it.

From streamlining operations to cutting lead times in half, our clients are achieving serious results. And they’re not keeping it to themselves.

Kaleris supports our customers through sincere partnerships. From enabling customer events between key stakeholders, offering support across regions, and guiding our customers from setup to adoption. We’re with you, every step of the way

Kaleris EVP is helping terminals worldwide simplify, scale, and succeed by fostering connectivity between ports and terminals and improving communication between key stakeholders.

Navis brought several customers together to discuss what the Navis TOS means to them and their terminals. Hear from Haifa Port, Hamburg Sud, Port Newark Container Terminal, Malta Freeports Limited, Modern Terminals Limited, YILPORT Holding Inc., Virginia International Terminals, and Cornelder de Mocambique about their experiences with N4.